Facilities

The Multiscale Mechanics and Nanotechnology laboratory occupies approximately 2,200 sq. ft. of modern research space. Research activities in the laboratory focus on fundamental and practical aspects of fluid transport, especially at length scales ranging from a few microns down to the nanometer level. Both experimental and theoretical aspects of fluid dynamic phenomena are investigated. The laboratory operates a hydrothermal setup featuring two autoclave units that are capable of prolonged operation at temperatures up to 1000°C and pressures up to 1000 bar. Several electrospinning and co-electrospinning setups are available in the laboratory. Also, two setups for inverstigation hydrodynamic and thermal aspects of drop cooling of high heat flux surfaces are available. All setups are operated within chemical hoods (six available), which allow the use of a wide array of chemical compounds. Additional support equipment available includes a Spectramax Gemini dual scanning microplate spectrofluorometer, which can perform a variety of fluorescent applications, including time-resolved fluorescent and luminescent assays. The lab is also equipped with furnaces that are sealed for controlled gas atmosphere experiments. Gas metering and control tools are also available. Other laboratory equipment includes a high-speed digital imaging system (Kodak, 10000 fps), several digital cameras (including a Nikon digital SLR, Nikon D3100 DSLR), high intensity lighting, high speed camera (phantom V210, 20000 fps), high-speed CCD-camera (Phantom Miro 4) observation capability of up to 40000 fps, three optical microscopes (including an Olympus BX51 instrument), rotational and elongational viscometers (including a Brookfield DV II+ programmable instrument), a gas-purged glove box, an inkjet printing system (MicroFab Technologies) for printed electronics, two differential scanning calorimeters (a DSC 2910 and a modulated DSC Q200, TA Instruments), an EFD spray robot, a temperature/humidity chamber (ESPEC SH-641), function generators, power supplies, amplifiers and other electronic devices, Atomic Absorption Spectrometer (AAnalyst200 obtained from Perkin Elmer), Instron machine (model 5942), Dake Compression Molder, Glove Box, Dynamic Mechanical Analysis (DMA) TA Instruments, The advanced electrochemical system GAMRI.

UIC Research Resources Center

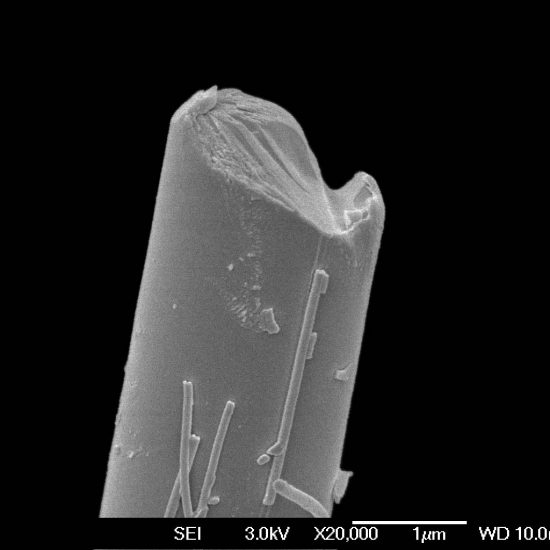

RRC personnel provide training and user access, as well as full professional services and expertise in material characterization studies. The multi-million dollar investment in equipment includes a JEOL 6320F Field Emission SEM, a SEM fitted with an EDD detector, a TopoMetrix Scanning Probe Microscope, a TEM/STEM with EDS and EELS, a JEM-3010, a TEM, a VG Microscope dedicated atomic-resolution STEM with EELS and Cs corrector for sub-Å resolution, a TEM for teaching and training, a Renishaw 2000 Raman microspectrometer, two mass spectrometers, and a JEOL JXA- 733 microprobe system. Specimen preparation equipment includes a Leica Ultramicrotome, a Fischione Plasma Cleaner, a Fischione Precision ion-mill, a Gatan Duo ion-mill and a Disc Cutter.

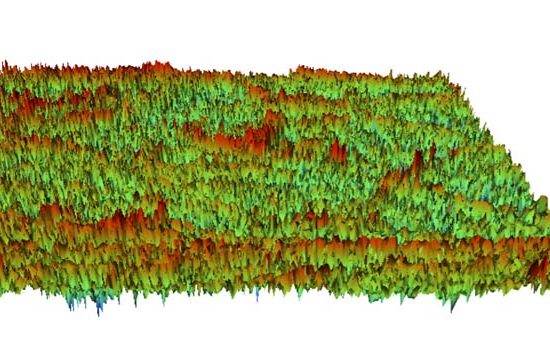

UIC Nanotechnology Core Facility

NCF is a versatile MEMS/Nano facility, which is accessible to university, non-profit and industrial researchers. The NCF enables research by providing access, training, service and process guidance on fabrication and characterization equipment. As a research and development laboratory, the NCF is dedicated to application of integrated circuit and fiber optic technology to improve manufacturing methods for MEMS/Nano devices, BioMEMS, Microfluidic, Electromechanical, Mechanical, Chemical, Optical, Photonic and multi-functional devices, some of which have previously been built by more traditional techniques. The NCF has versatile equipment for Photolithography (Mask Making capabilities, Mid/Deep-UV, top Fabrication (DRIE for Silicon & Silica, RIE, PECVD Oxidation/ Diffusion, LPCVD, RTP, Bulk and Surface Micromachining, Sputtering and E-beam metal evaporation, Polymer deposition and processing), Metrology (AFM, Optical & Contact Profilometry, Optical Inspection, Thin Film Stress Measurement), and Back-end processing (Dicing, Lead attachment and die bonding).